Why Are Stainless Steel Hydraulic Cylinders Used in Food Processing?

Stainless steel hydraulic cylinders are essential to the food processing industry because food processing involves a wide range of food products, from raw materials to finished products. As a result, any equipment in use must withstand the harsh conditions present in food processing environments, such as high pressure, temperature changes, and exposure to water, oils, and other corrosive substances.

You get durability, corrosion resistance, and standard hygiene maintenance with stainless steel hydraulic cylinders. In addition, these cylinders provide the best results for commercial and industrial food processing plants.

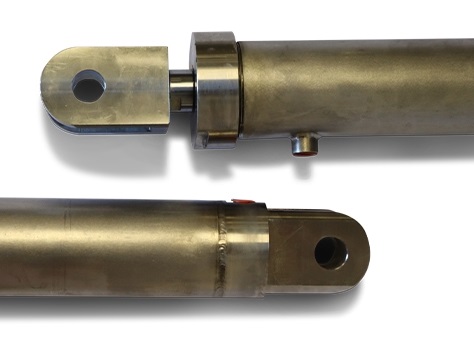

Understanding Stainless Steel Hydraulic Cylinders

Stainless steel hydraulic cylinders can deliver reliable and durable performance for commercial food processing industries. The stainless steel’s resistance to extreme food processing conditions helps the cylinders retain their strength and value. Additionally, they have strong resistance to pressure, temperature fluctuations, corrosion, and wear, making them appropriate for various applications.Food processing often involves harsh chemicals such as acids and alkalis that can damage equipment over time. However, stainless steel’s chemical corrosion resistance is significant in the food processing industry. Aside from their strength and durability, stainless steel hydraulic cylinders are considered hygienic because they are resistant to corrosion, bacteria, and other contaminants.

The smooth, non-porous surface of stainless steel prevents germ buildup and makes cleaning simple, allowing for a high level of sanitation. Furthermore, stainless steel does not react with food, chemicals, or water, making it ideal for critical applications of cleanliness and safety.

The Benefits of Stainless Steel for Food Processing

Stainless steel is widely used in food processing for many reasons, including durability, hygiene, and resistance to corrosion, staining, and tarnishing. These properties reduce downtime and maintenance costs and ensure that food is of the highest quality and safety, making it an effective and practical choice for food processors.For these reasons, people consider stainless steel cylinders for food processing. Below is a detailed analysis of these benefits:

Durability: One of the most important advantages of stainless steel is its durability. Stainless steel is a sturdy, strong material that is not easily damaged and can withstand the rigours of food processing environments. This quality makes them ideal for food processing equipment such as storage tanks, mixing bowls, and processing machines.

Hygiene: This is another important advantage of stainless steel because the material is non-porous, which means bacteria and other harmful substances cannot penetrate and grow. As a result, stainless steel is an excellent option for food processing facilities, as it prevents the spread of contamination and foodborne illness.

Corrosion resistance: Stainless steel is resistant to corrosion, staining, and tarnishing, making it ideal for food processing equipment that uses water or other liquids, as they will be rust-free. Additionally, stainless steel does not react with most acids, alkalis, and other chemicals, making it ideal for food processing applications that require dry cleaning.

Easy to clean: Another advantage of stainless steel is that it is easy to clean and maintain. The material’s smooth, non-porous surface makes it simple to clean and resistant to stains and fading, which makes it ideal for food processing equipment that requires frequent cleaning.

Heat resistance: Stainless steel has excellent heat resistance, making it suitable for food processing applications that require heating. The material will not warp or crack at high temperatures and will not absorb odours or flavours. This quality makes it ideal for food processing equipment used for cooking, baking, and even freezing. It also ensures that your equipment is always in good working condition.

Corrosion Resistance

The primary reason for using stainless steel hydraulic cylinders in the food industry is their high corrosion resistance. Steel consists of at least 10.5% chromium, which gives the material corrosion resistance. The material does not decompose or corrode in the presence of food, water, or other substances, making it ideal for food processing equipment and safe for use in food-related applications.

Another important property of stainless steel hydraulic cylinders is their washability. Food processing equipment should be thoroughly cleaned after each use to prevent contamination and ensure it is sanitary for the next batch of food. Also, stainless steel is corrosion-resistant, easy to clean, and has a smooth finish that won’t trap bacteria or other food debris. This characteristic is essential for food processing plants to maintain the highest level of hygiene and prevent food poisoning.

As well, stainless steel is durable, wear-resistant, and has a smooth surface that does not collect dirt. Its excellent corrosion resistance ensures it will not rust or deteriorate even in harsh environments. As a result, the hydraulic cylinder can be used without problems, even in rough and wet conditions.

By adopting a stainless steel hydraulic cylinder, the reliability of the food processing equipment and the sustainability of sanitation improves, enabling the production of high-quality food.

Precise hydraulic cylinder control ensures that food products meet required standards consistently, thus reducing waste and increasing profitability. Therefore, using stainless steel hydraulic cylinders in food processing is a wise investment to ensure safe, hygienic, and efficient production.

Finally, besides the food processing industry, stainless steel hydraulic cylinders are effective in sewage and water treatment facilities, maritime equipment, heat exchangers for ships, risers for oil platforms and pipelines, and material-handling facilities, among others.

Another important property of stainless steel hydraulic cylinders is their washability. Food processing equipment should be thoroughly cleaned after each use to prevent contamination and ensure it is sanitary for the next batch of food. Also, stainless steel is corrosion-resistant, easy to clean, and has a smooth finish that won’t trap bacteria or other food debris. This characteristic is essential for food processing plants to maintain the highest level of hygiene and prevent food poisoning.

As well, stainless steel is durable, wear-resistant, and has a smooth surface that does not collect dirt. Its excellent corrosion resistance ensures it will not rust or deteriorate even in harsh environments. As a result, the hydraulic cylinder can be used without problems, even in rough and wet conditions.

By adopting a stainless steel hydraulic cylinder, the reliability of the food processing equipment and the sustainability of sanitation improves, enabling the production of high-quality food.

Improve Food Processing With Stainless Steel Hydraulic Cylinders

For safe and hygienic food processing, stainless steel hydraulic cylinders are essential. They provide the right qualities for operating food processing machinery since they are manufactured from high-quality stainless steel and can withstand harsh conditions and demanding food processing environments. Consequently, hydraulic cylinders in food processing streamline production and improve efficiency.Precise hydraulic cylinder control ensures that food products meet required standards consistently, thus reducing waste and increasing profitability. Therefore, using stainless steel hydraulic cylinders in food processing is a wise investment to ensure safe, hygienic, and efficient production.

Finally, besides the food processing industry, stainless steel hydraulic cylinders are effective in sewage and water treatment facilities, maritime equipment, heat exchangers for ships, risers for oil platforms and pipelines, and material-handling facilities, among others.

Comments

Post a Comment