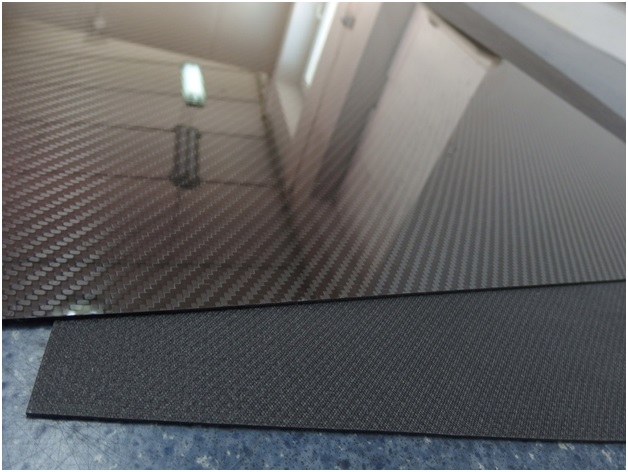

Carbon fibers are made of fine carbon atoms that are bonded together to form a long chain. The fibers are very strong, rigid and yet lightweight.

The material is 5 times stronger than steel and weighs just 1/3rd of its weight. Environmentalists feel that using this component for industrial and construction purposes could be beneficial for limiting pollution levels.

Carbon fiber composites are created by combining carbon fibers with other substances like plastic resin to produce carbon fiber polymer.

Carbon Fiber V/S Fiberglass

• Often mistaken to be fiberglass, carbon fiber is much stronger than it.• Fiberglass is just a polymer that contains silica glass weaving instead of carbon.

• Carbon fiber is flexible and popularly used in the manufacturing of high-value cars such as Lamborghini and Ferrari due to its immense strength and light-weight quality.

• Fiberglass is said to have good mechanical strength and its resistance qualities are greater than metals like steel

• Fiberglass is also a fine electric insulator even with very low thickness properties

• Fiberglass is incombustible as it is a mineral component and is naturally fire-proof

Carbon fiber V/S aluminum

• Carbon fiber is primarily used in those industrial areas where toughness and rigidity are essentially required in relation to the weight of the material used.• Industries related to aviation, racing cars, bicycles, automated machine-parts, and rehabilitation products.

• The unique design of the carbon fibers can be advantageous for luxury good manufacturers to make designer watches and wallets.

• Carbon fibers have to be molded and also baked to get the desired shapes. Carbon fibers are expensive when compared to metals.

• Aluminum, unlike carbon fiber, is uniform and isotropic in nature.

• Aluminum is also used in many manufacturing procedures.

• Aluminum can be welded, soldered, and extruded easily when compared to carbon fibers. Aluminum is cheaper than carbon fibers.

• The molding process of aluminum is much faster than carbon fibers.

Carbon Fibers V/S Steel

• Carbon fibers are almost 5 times tougher than steel• Carbon fibers are also 2 times stiffer than steel

• Carbon fiber is lighter in weight than steel and therefore ideal to be used as manufacturing materials

• Carbon fiber is thinner than a human hair strand and derives its strength when the fibers are twisted together

• Steel is one of the toughest metals in the market

• Steel is an alloy of iron and carbon

• Steel is a popular metal that is used for construction and building purposes

• Tools needed to make other manufacturing components are made of steel

• Steel is a low-cost metal and easy availability in the form of iron ores and scrap

• Steel has numerous mechanical properties

Carbon fiber is the backbone of any high-performance vehicles, racing cars, bikes, and motorboats. Experts believe that carbon fiber is the best component for modern manufacturing units. After years of research and development to source materials that offer safety and high-performance, carbon fiber composites became the unanimous choice of industries and manufacturing companies.

Formula One Racing Car Features

The formula one cars are based on advanced technology central monocoque system that protects the people who drive them. This car part is made of carbon fiber because it is extremely light in weight and provides powerful protection against all the tremendous forces that are involved in the racing sport.This protection is possible as carbon fibers are highly tensile and offer great torsional rigidity when the need arises. Carbon fiber is also flame-proof and non-corrosive. During adverse circumstances like an accident, it can shatter completely thus absorbing a huge amount of energy and saving the lives of people driving such cars.

Carbon Fibers Used in Making Other Car Components

Many other car parts like the gearbox and brakes are nowadays made from carbon fibers. This light-weight material has surpassed other traditional materials like steel and aluminum because of its weightless quality and awesome stopping power. Carbon fiber is the leading autoclave composite in the world, especially for producing car components that involve hundreds of man-hours, labor, and numerous stages of development like autoclaving and curing among other processes.For over a decade now carbon fiber has been used as the primary structural material in the sports industry. Nowadays, you will also find that carbon fibers are becoming the top-most choice for the construction of all types of cars.

Musical Instruments

Carbon fiber and many other composite substances are also used in the production of musical instruments. A company in Finland has successfully developed the very first flute that is entirely made of carbon fiber.This flute has been manufactured from a high tensile and coefficient carbon fiber material and has even managed to improve its acoustic qualities. The plan is also under-way to use carbon fiber in the making of guitars.

Scientific Uses of Carbon Fibers

Carbon fibers are extensively used in scientific experiments. One of the primary uses of carbon fibers includes making electrodes. A sheet of carbon fiber without resin properties but only having single-fiber carbon.The singles fibers are measured in diameters and preserved in narrow glass capillaries. Such electrodes are put in use in the neuroscience department to take measurements of cellular spikes that are active neurons present in the membranes.

Such electrode related experiments help determine the electrode noise level and usually a silver plated fine electrode of carbon fiber is used. Special scientific technology research known as the Voltammetric measurement is conducted with rats to release dopamine caused by electrical stimulation of the neurons.

Top-Model Planes and Spacecraft Designs

The technology reserved for developing satellites and unique plane models also depends heavily on carbon fibers and their extensive use. Again, due to its ideal weight, fire-resistance, and corrosion-free properties and superior strength, carbon fiber is an appropriate material to be put in use for manufacturing planes and spacecraft models.Thanks a lot for reading along. Don't forget to drop us a comment and share to your friends.